About us: Production process

-

Ageing of the clay

After extracting the clay, naturally transformed by the atmospheric agents, from the clay pit, it is mixed, milled, sifted and stored in a silo where it ages for from 2 to 3 years to guarantee the quality and resistance of the finished product.

-

Exclusively hand-molded

1. 'il pastone - the mix': the right quantity of plastic clay, well-rounded and compact, to make a brick or tile.

2. 'pressatura - pressing': a particular pressing for each tile or brick guarantees the correct compactness.

3. 'allisciatura - smoothing': smoothing first with a straight edge and then by hand perfects the pressing process.

4. 'posa del mattone - laying the tiles': the wet tiles or bricks are thrown on the ground where they will stay throughout the drying process. -

Natural drying

All the Sugaroni tiles and bricks are left to dry naturally, at which time they are trimmed, selected and turned around so as to furnish a properly dried perfectly level product.

-

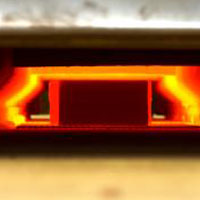

Firing with gas or wood

After 5 continuous days of firing with a peak temperature of 1057° C, the Sugaroni products become excellent resounding bricks and tiles.

-

Testing

Testing of the tiles and bricks after firing. Finishing and supplemental processing.